what do you call the rubber extrusion that provides stability to the lower sidewall and bead area

How a tire is fabricated

Tire Manufacturing

Anybody knows what a tire is and what it's for, correct? It's a blackness donut fabricated of rubber, placed on a vehicle so the driver can transport himself and his cargo from point A to bespeak B. The tire has to allow for easy steering, braking, and cornering. Information technology must provide for a comfortable, safe ride. It needs to be durable. And that's near the extent of what most of us know.

Use the tabs in a higher place to wait at the dissimilar stages of the manufacturing process.

SHOWING You WHAT WE'RE Made OF

RUBBER

Prophylactic Chemical compound Formulation

The two major ingredients in a condom compound are the prophylactic itself and the filler, combined in such a style as to achieve different objectives. Depending on the intended utilize of the tire, the objective may be to optimize performance, to maximize traction in both wet and dry conditions, or to achieve superior rolling resistance. The desired objective can be achieved through the careful pick of one or more types of safe, along with the type and amount of filler to alloy with the rubber.

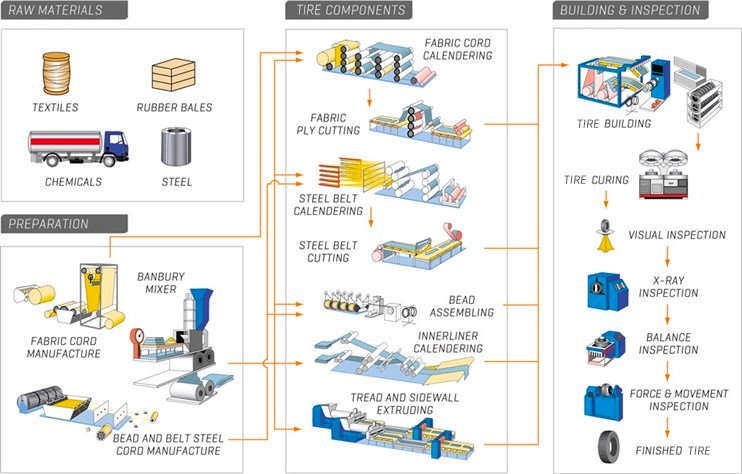

RAW MATERIALS

In general, at that place are iv major rubbers used: natural safe, styrene-butadiene safety (SBR), polybutadiene rubber (BR), and butyl rubber (along with halogenated butyl condom). The first iii are primarily used as tread and sidewall compounds, while butyl condom and halogenated butyl safety are primarily used for the inner liner or the inside portion that holds the compressed air inside the tire.

The most popular fillers are carbon black and silica, and there are several types of each. The selection depends on the operation requirements, as they are different for the tread, sidewall, and apex. Other ingredients as well come into play to assistance in the processing of the tire or to role every bit antioxidants, antiozonants, and anti-aging agents. In addition, the "cure packet"—a combination of curatives and accelerators—is used to course the tire and give information technology its elasticity.

Condom COMPOUND MIXING

Once the compound is determined, the adjacent claiming is how to mix information technology all together. The mixing operation is typically a batch operation, with each batch producing more than 200 kilograms of rubber compound in less than 3 to five minutes. The mixer is a sophisticated piece of heavy equipment with a mixing sleeping accommodation that has rotors inside. Its primary part is to interruption down the safe bale, fillers and chemicals and mix them with other ingredients.

The sequence in which the ingredients are added is critical, as is the mixing temperature, which tin ascent as loftier as 160-170 degrees Celsius. If the temperature is besides loftier, the compound can be damaged, so the mixing functioning is typically accomplished in 2 stages. The curative package is ordinarily added in the final stage of mixing, and the final mixing temperature cannot exceed 100-110 degrees Celsius or scorching may occur.

Once the mixing is completed, the batch is dumped out of the mixer and sent through a series of machines to form it into a continuous sheet called a "slap." The slap is so transferred to other areas for dewdrop wire associates preparation, inner liner calendering, steel and/or fabric belt/ply cord calendering, tire sidewall extrusion, and tire tread extrusion.

FABRIC AND STEEL

FABRIC AND STEEL

Because tires have to carry heavy loads, steel and cloth cords are used in the structure to reinforce the rubber chemical compound and provide strength. Among those materials suitable for the tire application: cotton, rayon, polyester, steel, fiberglass, and aramid.

FABRIC CORD

Fabric cord quality is based on its strength, stretch, shrinkage, and elasticity. The yarn used is start twisted and and so two or more spools of yarn are twisted into a string. Before aircraft the cord to the tire manufacturing plant, the manufacturer pre-treats the cord and applies an adhesive to promote good bonding with the rubber. The temperature, humidity and tension command are disquisitional before the fabric cords are calendered with the rubber compound. For this reason, fabric cord is kept in a temperature-and-humidity-controlled room once it arrives at the manufacturing plant.

STEEL CORD

Steel wire string quality is based on tensile strength, elongation, and stiffness. It is manufactured from steel rod with high carbon content; and while the steel wires used have dissimilar configurations, all are brass-coated strands twisted together into cords. If the wire is used in a multi-ply tire rather than a belted tire, the fatigue performance volition exist of import. If used in belted tires, and so stiffness is of primary concern. Since the steel wire is contumely coated, storage conditions are important to maintain the steel wire to rubber bonding properties. Therefore, the steel wires are too kept in a temperature and humidity controlled room once they arrive at the factory.

Belt AND PLY

To produce the material or steel belts, fabric or steel string must go through a calendering process—an operation in which the rubber compound is pressed on and into cords. Because the bonding of fabric to prophylactic or steel to rubber is critical to operation, the calendering procedure is an important step.

A calendar is a heavy-duty auto equipped with 3 or more chrome-plated steel rolls which circumduct in opposite directions. The roller temperature is controlled via steam and water. In this procedure, the rubber compound is applied to the cords.

Kickoff, a pre-set number of fabric or steel cords under proper tension are continuously pressed through two steel rollers, and prophylactic compound is added to the opening expanse between the rollers. And so the rubber chemical compound is pressed into, on superlative of and on the bottom of the textile or steel cords. A continuous sail of string-rubber composite goes through several more than rollers to ensure good penetration and bonding between the rubber and cords. Quality is measured by the thickness of the sail, spacing betwixt cords, the number of cords and the penetration of rubber into the blended sheet. The composite sheet is then cut into advisable sizes, shapes, and angles depending on the desired contour of the tire.

Dewdrop

The dewdrop component of the tire is a non-extensible composite loop that anchors the body plies and locks the tire on to the cycle assembly so that information technology volition non sideslip or rock the rim. The tire bead component includes the steel wire loop, apex or bead filler; the chafer, which protects the wire bead components; the chipper, which protects the lower sidewall; and the flipper, which helps hold the bead in identify. The bead wire loop is made from a continuous steel wire covered by safe and wound around with several continuous loops. The bead filler is made from a very hard rubber compound, which is extruded and then as to grade a wedge. The bead wire loop and dewdrop filler are assembled on a sophisticated car.

The precision of the dewdrop circumference is critical. If too small, tire mounting can be a problem; but if besides loose, the tire can come off the rim too easily under loading and cornering conditions. After the circumference is checked, the bead component is ready for the tire building operation.

TREAD

TREAD, SIDEWALL AND INNER LINER

Tyre tread, or the portion of the tire that comes in contact with the road, consists of the tread itself, tread shoulder and tread base. Three rubber compounds are extruded simultaneously from different extruders and are then merged into a shared extruder head. The adjacent move is to a die plate where the shape and dimensions are formed, then through a long cooling line – from 100 to 200 feet long – to further command and stabilize the dimensions. At the stop of the line, the tread is cutting co-ordinate to a specific length and weight for the tire being built.

THE TREAD AND SIDEWALL

Tyre components such as tread, sidewall, and apex are prepared by forcing uncured rubber chemical compound through an extruder to shape the tire tread or sidewall profiles. Extrusion is one of the most important operations in the tire manufacturing procedure because it processes most of the rubber compounds produced from the mixing functioning and so prepares diverse components for the ultimate tire edifice functioning.

The extruder in a tire manufacturing procedure is a screw-type organization, consisting primarily of an extruder butt and extruder head. First, the rubber chemical compound is fed into the extruder butt where it goes through a heating, blending, and pressurizing procedure. Then the rubber compound flows to the extruder head where it is shaped under pressure. The modernistic cold-feed extruder is calculator-controlled for accurateness.

SIDEWALL

The tire sidewall is extruded in a mode similar to the tire tread component; withal, its construction and the compound used are quite different from the tread. Sometimes the sidewall extrusion process tin can be more complicated and four extruders may be needed; for case, when edifice a tire with white sidewalls or with white lettering on the sidewalls.

INNER LINER

The inner liner is just what it sounds like – the inner-virtually layer of the tire. Its main functions are to retain the compressed air inside the tire and maintain tire pressure. Due to its low air permeability, butyl rubber – or halogenated butyl rubber compound – is the primary rubber chemical compound used. Because this is a thin layer it is as well produced using the calendar. The estimate control and no-defect surface terminate are disquisitional to retaining air pressure. Innerliner calendering is also a continuous operation. The proper length of the innerliner sheet is pre-cut to be ready for the tire building process.

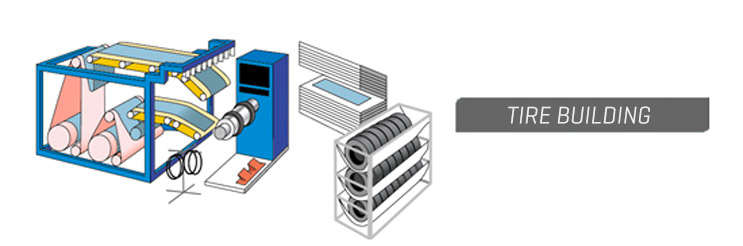

Building

Finally, the tire is ready to be built by a highly robotized automobile which ensures quality and efficiency. All components – bead assemblies, calendered plies, belts and inner liner, tread and sidewall sections – are assembled and the building process begins.

A typical radial tire is built on a flat pulsate in a two-stage process. In the first stage, the inner liner is wrapped around a pulsate and the first body ply is wrapped on top, followed by the second body ply. The bead assemblies are then positioned, and a bladder on the drum is inflated and pushed in from both ends of the pulsate, forcing the torso plies to plough up to cover the dewdrop assemblies. The sidewall sections are and then pressed on to both sides.

In the second stage of the tire edifice procedure, some other automobile is used to apply the belts, nylon cap, and tread on acme of the first stage. At this betoken, the tire still needs curing considering there is no tread pattern on information technology.

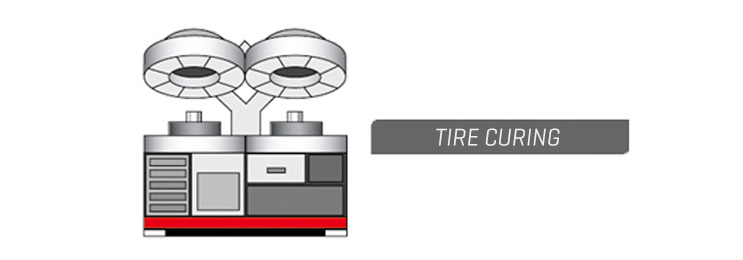

CURING

In this terminal step, curing occurs through a serial of chemic reactions. In addition, the sidewalls and tread are molded. Tyre curing is a high-temperature and loftier-pressure batch performance in which the uncured tire is placed into a mold at a specified temperature. Later on the mold is airtight, the safe compound flows into the mold which forms the tread details and sidewall. The mold cannot be opened until the curing reaction is completed.

INSPECTION

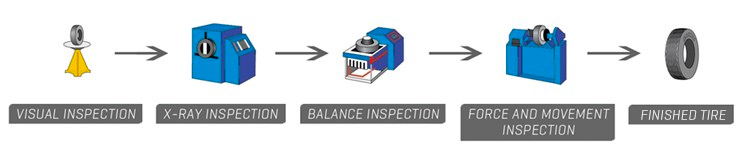

Tire inspection is the last step in the tire manufacturing process—an of import stride in ensuring quality in both performance and safety. The tire inspection includes:

Trimming of the mold wink and micro-vents

Visual inspection for appearance and to spot obvious defects

X-ray examination to check internal structure and to spot defects

Tyre immovability, uniformity, and weight balance inspection

Subsequently a tire passes these rigorous inspections information technology's time for the safety to meet the road! Our tire is prepare to be put into service.

Source: https://www.maxxis.com/uk/technology/how-a-tire-is-made/

0 Response to "what do you call the rubber extrusion that provides stability to the lower sidewall and bead area"

Post a Comment